Core Competency:Quality Engineering Services specializes in the design and manufacturing of fixtures, gages, and cast urethane products for the aerospace, military, and commercial industries.

Company Details:122 North Plains Industrial Rd.

Wallingford, Connecticut 06492

Key Contacts:

Name: Richard Addy

Title: Owner

Email: Email hidden; Javascript is required.

Name: Chuck Banik

Title: Senior Sales Engineer

Email: Email hidden; Javascript is required.

Name: Don Wildrick

Title:VP Sales & Marketing

Email:Email hidden; Javascript is required.

Name:Tom Addy

Title: General Manager

Email:Email hidden; Javascript is required.

Number of Employees:40

Special Technologies:

- Tool and Gage Manufacturing

- Tool Design

- Composite Tooling

- Prototype Machining

- Additive Manufacturing

- Cast Urethane and RTV Silicone Mold Making

Materials:

Aluminum Alloys, Brass, Bronze Alloys, Polymers, Silicone, Rubber, Polyurethane, Stainless Steel Alloys, Steel Alloys, Titanium Alloys

Part Size Ranges:

1" - 6", 12" - 24", 24" - 60", 6" - 12"

Quality Certifications:

General Dynamics Electric Boat, General Electric, ISO 9001, Kaman Aerospace, Lockheed Martin, Pratt & Whitney, Pratt & Whitney Canada, Rolls Royce, Sikorsky Aircraft, Collins (UTAS/Hamilton)

Processes:

Abrasive Blasting, Abrasive Waterjet Cutting, AirFlow Inspection, Aluminum Finishing - Anodizing, Aluminum Finishing - Chemfilm, Assembly Operations, Balancing, Bar Cutting, Broaching, Drilling, EDM / ECM, Fabrication, General Machining Processes, Grinding - Blanchard, Grinding - CBN, Grinding - Centerless, Grinding - Flat Surfaces, Grinding - ID or OD Surfaces, Gun Drilling, Heat Treat (Aluminum), Heat Treating, Heat Treating, Carburizing, Heat Treating, Nitriding, Honing, Jig Bore, Jig Grinding, Lapping, Laser Cutting, Laser Part Marking, Media Blasting, Milling, Milling - 5 axis, Mold Manufacturing, Non-Destructive Testing, NonDestructive Testing (Magnetic Particle Insp), Painting, Passivation, Plastic Molding - Hi Temp, Plating - Nickel, Zinc Nickel, Pressure Testing, Rubber Molding, Sheet Metal Fabr, Spline Shaping / Grinding / Hobbing, Tube Bending, Turning, Turning - Hard, WaterJet Cutting, Welding (Arc, Tig), Welding (Laser), Epoxy Bonding, Plating - Electroless Nickel, Plating - Zinc, Milling - 3, 4 & 5 axis, Mill/Turn, Grinding, Sawing, Cast Urethane, RTV Silicone, Part Protection- 167

- 142

- 110

- 295

- 296

- 90

- 148

- 152

- 61

- 52

- 57

- 139

- 49

- 161

- 102

- 210

- 54

- 55

- 53

- 193

- 123

- 258

- 259

- 175

- 149

- 143

- 146

- 60

- 268

- 242

- 51

- 128

- 275

- 292

- 190

- 155

- 239

- 177

- 293

- 87

- 200

- 158

- 59

- 204

- 50

- 164

- 231

- 58

- 250

- 3002

- 3007

- 3008

- 3013

- 3014

- 3015

- 3016

- 3019

- 3020

- 3021

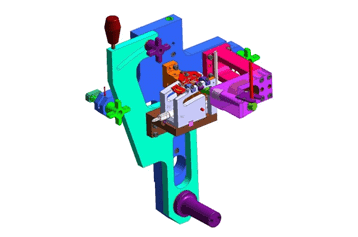

Tool Design

Tool Design

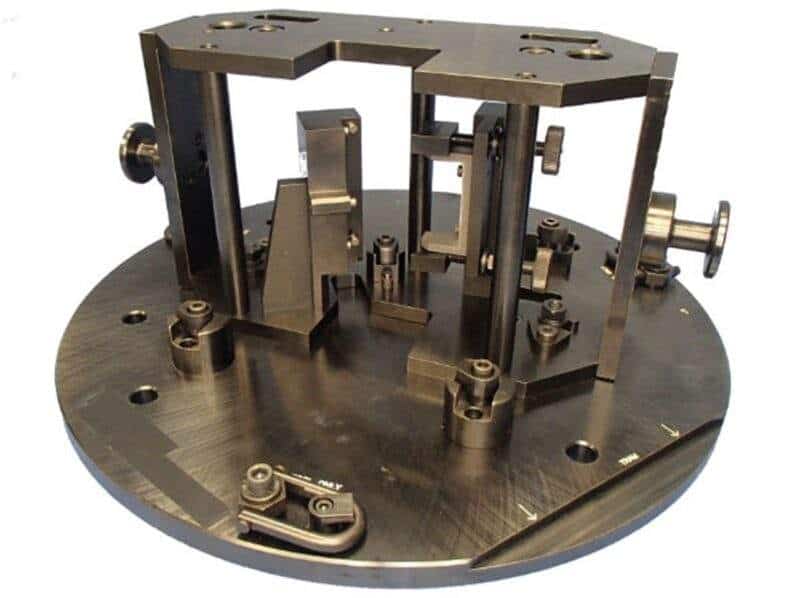

Fixture and Gage Manufacturing

Fixture and Gage Manufacturing

Cast Urethane and RTV Silicone part protection and molded masking

Cast Urethane and RTV Silicone part protection and molded masking

Prototype Machining

Prototype Machining