Core Competency:Interstate Manufacturing Company, Inc. provides design, fabrication and industrial supply solutions to government agencies and prime contractors for the purpose of fulfilling urgent as well as long term requirements and occupies a modern 17,500 square foot facility. In addition to the tool design, CNC machining and tool-making services, IMC has expanded its services to include Rapid Prototyping for the purpose of turning an idea into a 3D Model and then into a physical nylon part for testing fit & function and in many cases, end use. In house welding & fabricating services are offered to compliment our machining services and to reduce lead times. Siemens NX and Solidworks are used in the Tool Design process and latest Mastercam is utilized throughout the manufacturing process including 2D and full 3D - multi-axis surfacing operations.

Company Details:84 Gold Street

Agawam

Massachusetts 01001

Key Contacts:

Name: Keith J. Stone

Title: President

Email: Email hidden; Javascript is required.

Name: James Stone

Title: Operations Manager

Email: Email hidden; Javascript is required.

Number of Employees:12

Materials:

Aluminum Alloys, Bronze Alloys, Copper Alloys, Nylon - Glass Filled, PEEK, Polymers, Silicone, Rubber, Polyurethane, Stainless Steel Alloys, Steel Alloys, Titanium Alloys, Aluminum Bronze- 40

- 141

- 140

- 184

- 185

- 201

- 43

- 44

- 45

- 4003

Part Size Ranges:

1" - 6", 12" - 24", 24" - 60", 6" - 12"

Quality Certifications:

General Electric, Kaman Aerospace, Pratt & Whitney, Collins (UTAS/Hamilton)

Processes:

3D Printing / Additive Manufacturing, Abrasive Waterjet Cutting, EDM / ECM, Fabrication, General Machining Processes, Grinding - Blanchard, Grinding - Flat Surfaces, Grinding - ID or OD Surfaces, Honing, Jig Bore, Milling, Milling - 5 axis, Turning, Welding (Arc, Tig)- 273

- 142

- 57

- 139

- 49

- 161

- 54

- 55

- 175

- 149

- 51

- 128

- 50

- 58

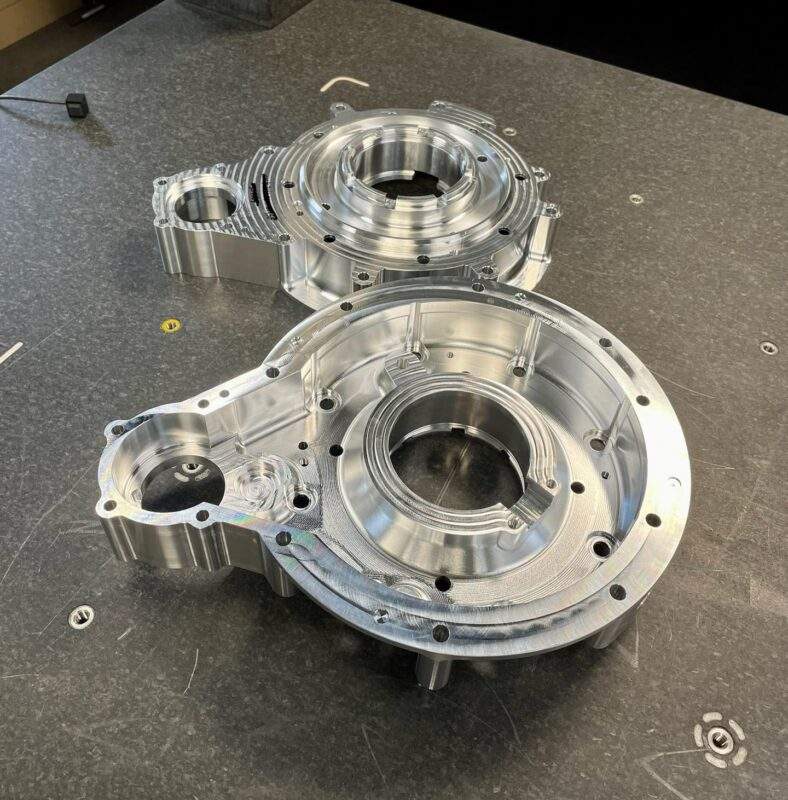

IMC 5-axis HURCO CNC

IMC 5-axis HURCO CNC

IMC 5-axix Parts - Aircraft Fittings

IMC 5-axix Parts - Aircraft Fittings

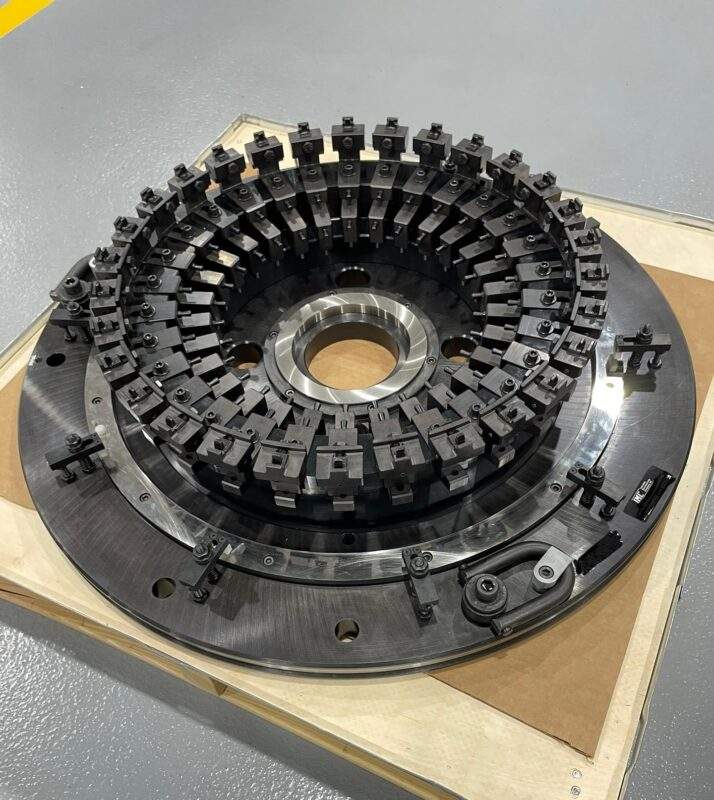

IMC Tooling Fixture - Aircraft Engine

IMC Tooling Fixture - Aircraft Engine

IMC Turned Parts - Aircraft

IMC Turned Parts - Aircraft