To download a listing of ACM members: ACM Membership List 11.14.25

Birk Manufacturing is a world leader in the design and manufacture of flexible heaters, temperature sensors and thermal systems. Over 35 years of experience in critical aerospace applications such as military, commercial and private aircraft, satellites, avionics, optics, instrumentation and more . Birk is ISO 9001, 13485, and AS9100 certified and holds NIST SP 800-171 and IPC J-STD-001HS space and military addendum, NASA S-311-P079 & NASA S-311-P841 certifications and is ITAR registered.

Special Technologies:

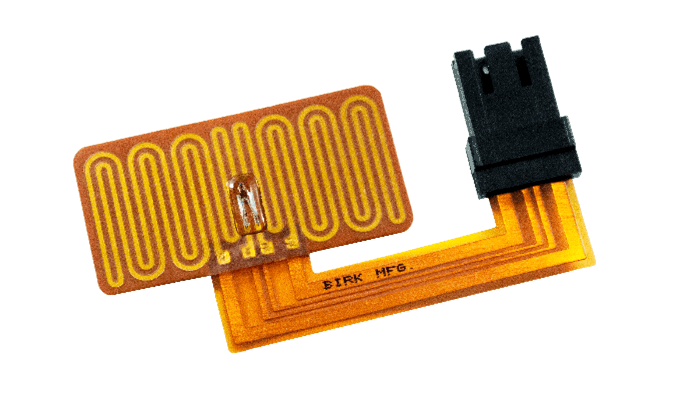

Pictured is a flexible Polyimide (Kapton®) heater. Capable of reaching temperatures up to 500⁰F this heater incorporates a thermistor (temperature sensor), a non-heated flex tail providing an electrical signal through the zero-insertion force (ZIF) connector on the termination end.

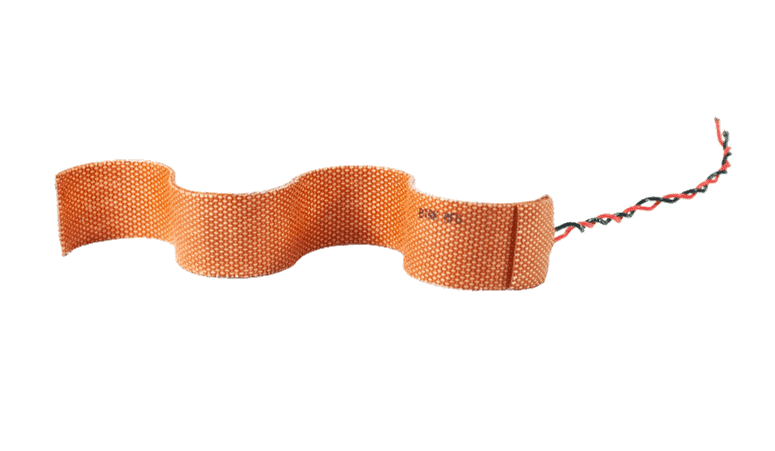

Pictured is a flexible Silicone heater. Capable of reaching temperatures up to 400⁰F this heater is formed to a specific shape to nest between battery packs.

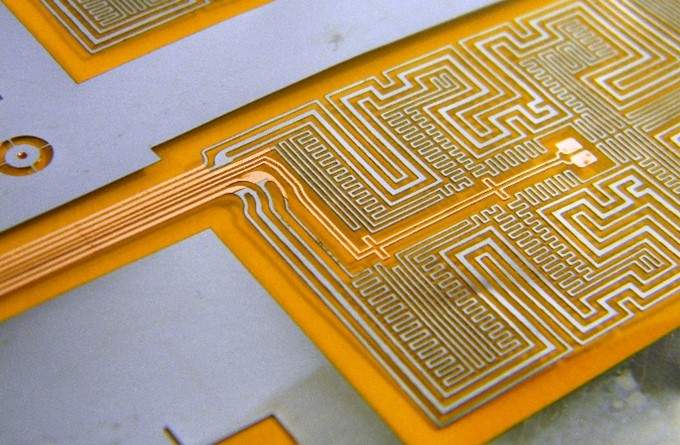

Pictured is an etched circuit on Polyimide (Kapton®) with gold plating over non-heated sensor traces and flex tail.

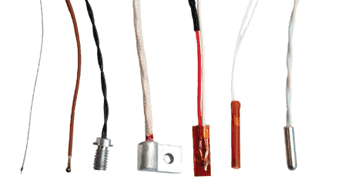

Pictured are various types of temperature sensors including thermocouples, RTDs and thermistors housed in ring and screw terminals, Kapton®, metal probe housing along with other options available.